Pipe extrusion lines

Dextec single Screw Extruders are produced with Germany’s most advanced technology. Only CE and ISO 9001 Quality Certificate approved components have been used in its production. With our Single Screw Extruders, each being an engineering and technological marvel, you can increase your production capacity from a minimum up to 700kg/hour and manufacture pipes having a diameter ranging between 8 mm to 630 mm with polyethylene and polypropylene raw materials.

The range of our single screw extruders vary from the smallest co-extruder with 20mm of diameter up to the biggest one with 90mm. The screw length / diameter ratio called L/D ratio varies from 20 up to 36, depending on pipe diameter and material used.

» Dextec computerized control panels

Dextec computerized control panels are produced by using the most advanced technology.

Dextec electrical cabinet consist of the newest components all Made in Germany.

» Dextec heating cooling combination

Dextec heating cooling combination uses the highest quality resistors. Heating is extremely important while working with plastic raw materials.

Our ceramic heating elements induct the thermal energy directly into the barrel, avoiding any loss of energy in the air.

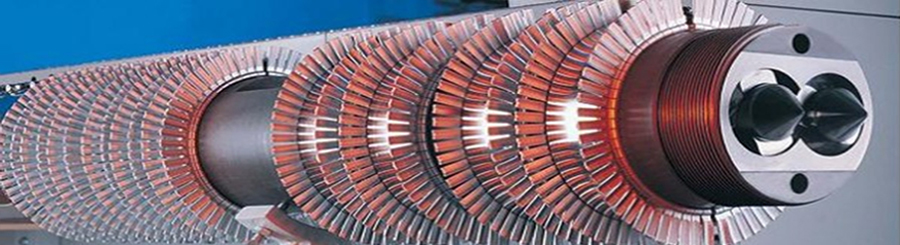

» Dextec screws and barrels

are made of only top quality nitrated steel. We use the highest technology of geometry engineering and modeling techniques in the production and again do not make concession on the quality of the machines. We use special steel in the production of screws and thus obtain a maximum surface hardness and smoothness. We ensure homogenous distribution of heat on screw surface and hence maximize the wear resistance. We provide you with options of turning the screws from outward to inward, inward to outward and to the same direction in order to provide the best mixing for your raw material.

The barrels are designed to have a multi-zone characteristic. In this way you can apply different temperatures at different zones which increase the quality of the plasticizing and save energy.

» Dextec gear boxes

Dextec gear boxes are a robust special construction for a long lifetime. The oil change on our gear boxes can be done first after ca. 10.000 hours of service. All our gear boxes are manufactured to operate safely at high torques.

» Dextec pipe heads

As a result of special pipe heads design we provide homogeneous and harmonious distribution of melted mass. Because of choosing right and high chrome alloyed steel our pin and nozzles have long-term working life. Of course due to such sensitivity of our company our clients are obtaining pipes with a very smooth surface and high quality.

» Dextec vacuum and spray pipe tanks

We provide you with alternatives of vacuum and Spray Pipe tanks for your excellent production. We use the top quality material in

tanks without any concession quality. You also have an option of open top pipe tanks.

» Dextec haul off unit

Synchronization is very important in extrusion process. Thus, we provide you with hi-tech Haul-Off units. We supply pipe haul-off with options of pallet width changing according to pipe diameter, adjustable haul-off speed and adjustable pressing capability for perfect production. We prepare double or multi-arm hauling alternatives in pipe haul-off. In order to minimize erosion, we choose special palettes. You can also control production either from control panel or on the machine as well.

» Dextec pipe saw

Profile extrusion lines

» Twin screw Extruder

Dextec twin screw Extruders are produced with Germany’s most advanced technology. Only CE and ISO 9001 Quality Certificate approved components have been used in its assembly. With the twin screw Extruders, each being an engineering and technological marvel, you can increase your production capacity from 50-60 kg/hour up to 1500 kg/hour.

Dextec extruders are designed for profiles, window sills, specific type profiles, complex profiles, pipes and granulation.

Raw material mixing is extremely important for the quality of your production. For this reason dosage units which can transfer the raw material volumetrically or gravimetrically are used in our Extruders.

» Dextec heating cooling systems

Dextec heating cooling systems avoid facing problems in the event of overheating of the raw material. The cooling fans used in our Extruders stabilize the heat and keep the process away from such risks.

» Touch screen panel

For providing a perfectly running system that is under your control and surveillance during production we use specially developed TFT touch screen industrial PC and PLC. In order to obtain full control in the system together with high experienced European partners we have developed special software. With this special program, we are able to develop receipt and plans of work according to the raw material or production profile; to save time by one touch operation of any selected program and to make synchronization adjustment of production line at will. The control panel has an ideal position for your comfort in the process of plastic extrusion.

Electric cabinet. The electric cabinet is base on most modern components, with all CE and ISO certificate for a safe work of the extruder.

» Dextec twin screws and barrels

Dextec twin screws and barrels are made from the highest steel quality.

We use the highest technology of geometry engineering and modeling techniques in the production of the twin screws and the barrels.

Dextec does not make concession on the quality of the twin screws and the barrels used in all our twin screw extruders. We use special steel in the production of screws and thus obtain a maximum surface hardness and smoothness. We ensure homogenous distribution of heat on the screws’ surface and hence maximize the wear resistance.

Dextec provides options on screw geometry, as well as special coating technologies to increase the output, to improve the plasticizing and reduce the wear.

» Calibration table

Dextec Calibrator Table is specially designed for higher efficiency and stability

of profile calibrator. Water and vacuum connections of calibrator tables can be

easily increased according to profile type. Equilibrium adjustments required for

production (upward - downward, forward - backward, balance, etc.) are designed

either as manual or automatic according to the models of machines.

Vacuum and water valves.

Distribution of water is specially designed for the best cooling without any damage to profile surface from water drops and static energy on the manufactured product.

» Profile haul off units.

We supply Profile haul-off equipped with a pallet width varying from 200 to 600 mm, adjustable hauling speed between 0,2m/min and 30 m/min and with adjustable pressing capability for perfect production. We also supply profile haul-off with alternatives enabling you to perform automatic, semi-automatic or manual lubrication and adjustable haul-off palettes for technical and special profiles.

Haul off palettes.

We are equipping special palettes for our haul off units in order to minimize erosion. We supply belt type haul-off for thin flesh and decoration profiles as well.

» Profile cutting machinery.

Dextec saw blades have a special thin design preventing formation of burrs and dust. Our encoder and switch systems will enable to have the desired cutting length during production. You can individually determine the cutting shape by using vertical or planetary saw blades with a diameter up to 500 mm. Saws can also be installed independent from the haul-off upon your request.

Dextec saw blades have a special thin design preventing formation of burrs and dust. Our encoder and switch systems will enable to have the desired cutting length during production. You can individually determine the cutting shape by using vertical or planetary saw blades with a diameter up to 500 mm. Saws can also be installed independent from the haul-off upon your request.Images:

1) Profile cutting unit

2) Shutter perforating unit